What Is a Spreader Bar?

If you’ve ever seen a crane lifting a large object or a hammock suspended perfectly, you’ve likely encountered a spreader bar — even if you didn’t know it. So, what is a spreader bar?

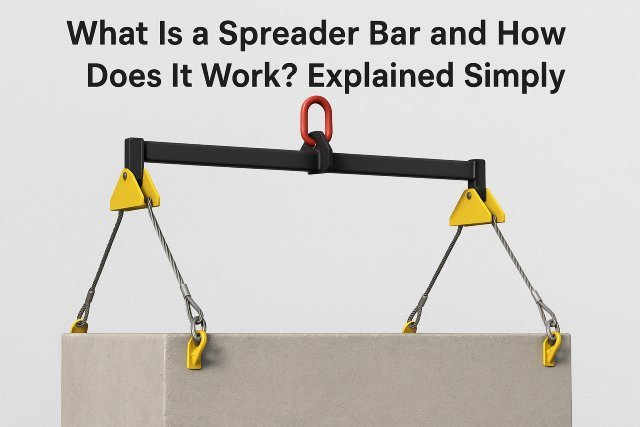

In simple terms, a spreader bar is a beam or bar that distributes load evenly across multiple lifting points. It’s commonly used in rigging, construction, shipping, and even sports or BDSM equipment to improve balance, safety, and comfort.

Spreader bars may look simple, but their design plays a crucial role in stability, efficiency, and safety in many industries.

What Does a Spreader Bar Do?

At its core, the spreader bar’s job is to spread out the load.

Instead of suspending a heavy or wide object from a single lifting point (which could damage the object or the lifting gear), the bar connects to multiple slings or chains, keeping the load balanced and the lifting angle safe.

Key Functions:

- Distribute load evenly across attachment points

- Reduce stress on slings, hooks, and crane booms

- Prevent deformation of delicate or long loads

- Enhance safety by keeping slings at optimal angles

For example, in crane operations, lifting a long steel beam without a spreader bar could cause it to bend or twist. With a spreader bar, the beam remains level and secure.

How Does a Spreader Bar Work?

A spreader bar works as a compression member — it resists being squeezed between two points. The slings or chains attached to its ends pull inward, while the bar itself pushes outward to maintain spacing and stability.

Here’s a simplified breakdown:

| Component | Function |

|---|---|

| Bar/Beam | The main body that resists compression. |

| End Fittings | Connect slings, hooks, or shackles to the bar. |

| Top Sling(s) | Connect the bar to the crane hook or lifting device. |

| Bottom Slings | Attach to the load being lifted. |

When in use, the forces balance out — tension runs through the slings, and compression runs through the spreader bar, allowing heavy or wide loads to be lifted safely and evenly.

Common Types of Spreader Bars

Different applications call for different spreader bar designs. Here are the most common types:

1. Fixed Spreader Bar

- A single, solid bar with set length.

- Ideal for lifting loads of known and consistent dimensions.

- Often used in factories and shipyards.

2. Adjustable Spreader Bar

- Length can be adjusted using telescoping sections or pinned holes.

- Provides greater flexibility for varying load sizes.

3. Modular Spreader Bar

- Assembled from multiple sections using bolts or couplers.

- Extremely versatile and suitable for heavy-duty industrial use.

- Can form configurations like H-frames or multiple spreaders.

4. Hammock Spreader Bar

- Found in hammocks or swings to keep fabric spread out.

- Ensures comfort and prevents tangling.

5. BDSM or Sports Spreader Bars

- Used for restraint or positioning, typically connecting limbs.

- Designed for safety and comfort, not load-bearing.

Applications of Spreader Bars Across Industries

1. Construction and Rigging

Used for lifting steel beams, pipes, machinery, and containers.

Example: A construction crane lifting a long pipe with two-point attachment via a spreader bar prevents bending.

2. Shipping and Marine

Ships and ports use spreader bars for container handling.

They ensure balanced lifting during cargo transfer.

3. Aerospace and Manufacturing

Used to lift delicate or precision-engineered parts without deforming them.

4. Recreational Use

From hammocks to paragliding, spreader bars improve comfort and stability.

5. Medical and Therapy Equipment

Some mobility and patient lifts use spreader bars to distribute weight evenly for safer transfers.

Advantages of Using a Spreader Bar

| Advantage | Description |

|---|---|

| Safety | Keeps slings at safe angles, reducing risk of failure. |

| Load Protection | Prevents bending or crushing delicate materials. |

| Efficiency | Simplifies lifting of wide or uneven loads. |

| Versatility | Adjustable or modular models fit multiple applications. |

| Cost-Effective | Reduces equipment wear and potential damage costs. |

Spreader Bar vs. Lifting Beam: What’s the Difference?

Many people confuse spreader bars with lifting beams, but they’re not the same.

| Feature | Spreader Bar | Lifting Beam |

|---|---|---|

| Force Type | Compression | Bending |

| Load Distribution | Suspended by slings | Suspended directly under hook |

| Weight | Lighter | Heavier |

| Ideal For | Wide loads, adjustable configurations | Low headroom situations |

In short, if you have enough headroom, a spreader bar is usually more efficient and safer for wide loads.

Safety Tips for Using Spreader Bars

- Always check the load capacity (Working Load Limit) before lifting.

- Inspect fittings, welds, and slings for damage or corrosion.

- Use certified lifting equipment that meets ASME and OSHA standards.

- Ensure load balance — uneven slings can cause dangerous swings.

- Store bars properly to avoid deformation or rust.

FAQs About Spreader Bars

1. What is a spreader bar used for in rigging?

A spreader bar is used to lift large or heavy loads evenly by spreading the force across multiple slings.

2. How is a spreader bar different from a lifting beam?

A spreader bar handles compressive forces, while a lifting beam resists bending forces.

3. Can I make my own spreader bar?

For non-industrial use (like hammocks), yes.

For lifting loads, never DIY — use certified, engineered bars only.

4. What materials are spreader bars made from?

Most industrial bars are made from high-strength steel or aluminum alloys, while recreational ones may use wood or carbon fiber.

Conclusion: The Role of Spreader Bars in Safety and Efficiency

So, what is a spreader bar?

It’s a deceptively simple yet essential tool that makes lifting, balancing, and supporting loads safer and more efficient across multiple industries.

Whether it’s a crane hoisting steel, a sailboat maintaining mast stability, or a hammock keeping its shape, spreader bars quietly do the heavy lifting — literally.

When used correctly, spreader bars not only protect the load and workers but also improve productivity, reduce wear on equipment, and uphold safety standards.