What Is Diaseal?

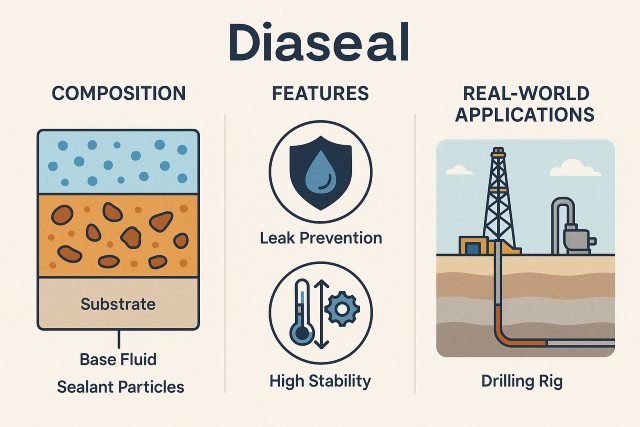

Diaseal is a high-performance sealing and fluid loss control material engineered for use in industrial, drilling, and construction applications. Known for its superior adaptability and efficiency, Diaseal plays a crucial role in preventing fluid leakage and stabilizing systems where pressure or temperature fluctuations are common.

In simple terms, Diaseal ensures reliable sealing performance even under extreme environmental or operational conditions — making it indispensable in industries such as oil & gas, automotive, construction, and manufacturing.

Composition of Diaseal

At its core, Diaseal is designed with a blend of organic and inorganic polymers that enable excellent sealing, durability, and thermal resistance. The exact formulation can vary based on industry-specific requirements, but typical Diaseal compositions include:

| Component | Function | Description |

|---|---|---|

| Elastomeric Polymers | Flexibility & elasticity | Provides expansion and contraction under varying pressures. |

| Fibrous Fillers | Strength & reinforcement | Enhances sealing under high mechanical stress. |

| Resins or Binders | Structural integrity | Ensures cohesive bonding of materials. |

| Thermal Stabilizers | Heat resistance | Maintains seal performance under extreme temperatures. |

| Lubricating Agents | Reduced friction | Prevents wear during movement or operation. |

These components collectively make Diaseal ideal for high-pressure fluid control and anti-leak applications in complex engineering environments.

Key Features of Diaseal

1. Exceptional Sealing Efficiency

Diaseal’s unique molecular structure provides tight sealing across wide pressure and temperature ranges. This minimizes fluid loss, boosts efficiency, and extends system lifespan.

2. Chemical and Thermal Resistance

Engineered for harsh environments, Diaseal resists degradation from corrosive fluids, hydrocarbons, and extreme temperatures — a vital feature in oilfield and industrial uses.

3. Versatility

Available in multiple grades and viscosities, Diaseal adapts to various sealing systems such as gaskets, O-rings, plugs, and wellbore seals.

4. Environmental Safety

Modern formulations of Diaseal comply with environmental safety standards, often being non-toxic and biodegradable, depending on the application.

5. Easy Application

Whether used in downhole sealing, pipeline maintenance, or equipment assembly, Diaseal is easy to mix, pump, or apply, reducing downtime and maintenance costs.

How Diaseal Works

Diaseal operates on a mechanical and chemical sealing principle. When applied between two surfaces or within a wellbore, it:

- Expands upon contact with fluid or pressure.

- Forms a strong adhesive bond with the surrounding material.

- Prevents any further movement of fluid or gas.

- Maintains its structure even when subjected to vibration, pressure cycling, or high heat.

This makes Diaseal an active sealing compound rather than a passive filler — ideal for dynamic systems such as drilling muds and hydraulic assemblies.

Real-World Applications of Diaseal

1. Oil and Gas Drilling

One of the most prominent uses of Diaseal is in wellbore strengthening and fluid loss control.

It prevents lost circulation by sealing permeable formations, thereby enhancing drilling efficiency and reducing non-productive time.

Example:

In offshore drilling, Diaseal formulations are injected into wellbore zones prone to leaks. The material expands and solidifies, effectively plugging micro-fractures and stabilizing pressure zones.

2. Automotive and Mechanical Engineering

Diaseal compounds are used to seal joints, gaskets, and fuel systems. Their resistance to oils, coolants, and fuels ensures long-lasting performance in engines and pumps.

3. Civil Engineering

In construction and tunneling, Diaseal helps prevent groundwater ingress and seal expansion joints in concrete structures—ensuring structural stability and durability.

4. Aerospace Applications

Due to its lightweight yet strong sealing properties, Diaseal is also utilized in aircraft hydraulics and fuel systems, maintaining performance under extreme conditions.

Advantages of Using Diaseal

- Reduces downtime caused by leaks or seal failures

- Improves operational safety in high-pressure environments

- Compatible with multiple substrates (metal, concrete, composites)

- Minimizes environmental risk due to leak prevention

- Long service life, even under repeated mechanical stress

Diaseal vs. Conventional Sealants

| Feature | Diaseal | Conventional Sealants |

|---|---|---|

| Pressure Resistance | Up to 10,000 psi | 2,000–5,000 psi |

| Temperature Range | -40°C to 250°C | -10°C to 120°C |

| Chemical Compatibility | Excellent | Moderate |

| Flexibility | High | Medium |

| Environmental Compliance | Advanced eco-friendly options | Often solvent-based |

Clearly, Diaseal outperforms conventional sealants in critical industrial environments.

FAQs About Diaseal

Q1: What is the shelf life of Diaseal?

Typically, Diaseal can be stored for 12–24 months under dry, cool conditions. Always check manufacturer guidelines.

Q2: Can Diaseal be reused after curing?

No. Once Diaseal cures, it forms a permanent seal that cannot be remolded or reused.

Q3: Is Diaseal compatible with synthetic drilling fluids?

Yes. Most Diaseal variants are formulated for compatibility with both water-based and oil-based drilling fluids.

Q4: What safety precautions should be taken when handling Diaseal?

Use protective gloves and eye gear, and ensure adequate ventilation during application.

Best Practices for Using Diaseal

- Clean and prepare the surface or borehole before application.

- Mix thoroughly according to manufacturer’s ratio.

- Apply evenly to ensure consistent sealing.

- Allow adequate curing time under controlled conditions.

- Conduct pressure testing before resuming operations.

Following these steps ensures optimal performance and long-term reliability.

Conclusion: Why Diaseal Stands Out

In today’s industrial world, where efficiency and reliability are paramount, Diaseal has proven to be a game-changer. Its advanced composition, exceptional sealing capabilities, and versatile applications make it one of the most trusted sealing solutions globally.

Whether in oilfield drilling, construction, or mechanical systems, Diaseal delivers consistent results under the toughest conditions — ensuring safety, sustainability, and operational success.